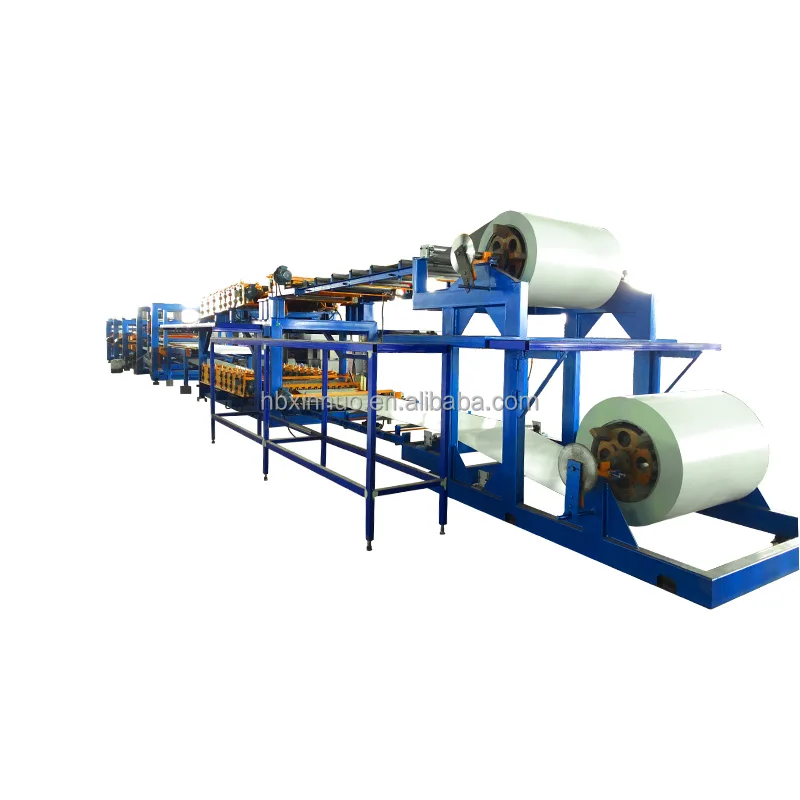

| Che. | paramethara e kholo ea mochini oa mochini oa Sandwich | ||

| 1 | E loketse ho sebetsa | Letlapa la tšepe la 'mala | |

| 2 | Bophara ba poleiti | 1000&1200mm | |

| 3 | Lirolara | 17-44 mela | |

| 4 | Litekanyo | 38.0 * 2.25 * 2.5m | |

| 5 | Matla | 30kw | |

| 6 | Botenya ba poleiti | 0.3-0.8mm | |

| 7 | Tlhahiso | 2-6m/min | |

| 8 | Diameter ea rolara | Φ90 limilimithara | |

| 9 | Boima ba 'mele | Hoo e ka bang 15 T | |

| 10 | Palo ea li-volts | 380V 50Hz 3 mekhahlelo | |

| 11 | Boitsebiso ba poleiti ea ho itšeha | Cr12 | |

| 12 | Ts'ebetso e nepahetseng | Ka hare ho 1.00mm | |

| 13 | Tsamaiso ea taolo | Taolo ea PLC | |

| litekanyetso tsa sandwich panel | |

| Bolelele | Bolelele bo fokolang: 3 m Boholo ba bolelele ba stacker: 15 m |

| litekanyetso tsa thepa e tala | |

| Botenya ba khoele | 0.4 ~ 0.6mm (ka holim'a coil e lokela ho ba sephara, ha ho na arch mme tse ling li hlahisa mathata.) |

| Matla a tlhahiso ea coil | 235MPa |

| Material coil max bophara | sheba litšoantšo tse hlakileng tsa profil. |

| Boima ba lisebelisoa tsa coil | 5 T |

| Material coil bophara ba ka hare | Φ508,Φ610 limilimithara |

| Lintho tsa mantlha tsa EPS | |

| tekano | ≥18Kg/m3 |

| sekhahla se otlolohileng | ≤1mm/m |

| degree ea arch | ≤3mm/m |

| bokaholimo ba phanele | shoule be flat ha ho na degree e bataletseng e ≤1.5mm/m, |

| bolelele ba phanele ea sandwich | bolelele ho feta 5 metres |

| thepa ea boea | |

| bolelele ba fiber | ≥100mm |

| boima ba cubage | ≥100Kg/m3 |

| bolelele ba phanele ea sandwich | ≥3 limithara |

| Lintlha tsa Pakete: | Mochini o ka sehloohong o hlobotse, lebokose la taolo ea k'homphieutha le tletse ka foreimi ea lepolanka. |

| Mochini o ka sehloohong o hlobotse ka har'a sets'oants'o, lebokose la taolo ea komporo e tletse ka liphutheloana tsa lehong. | |

| Lintlha tsa thomello: | Matsatsi a 20 |

♦ PALE EA BOPHELO BA HAE:

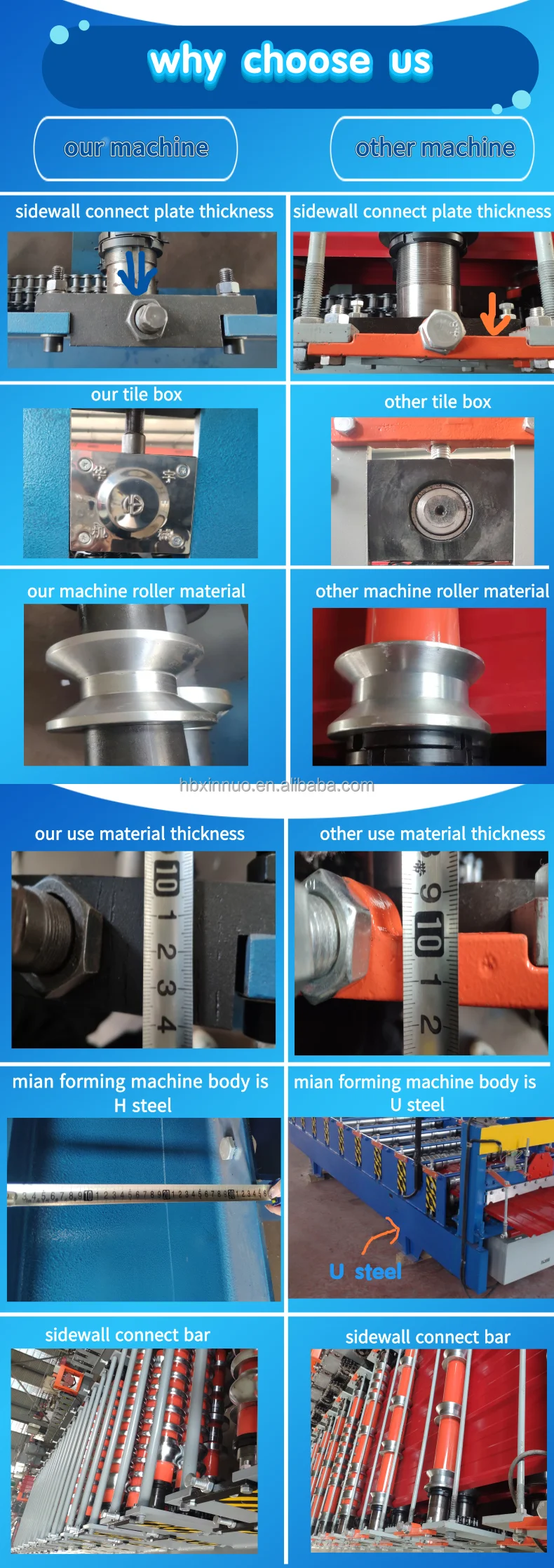

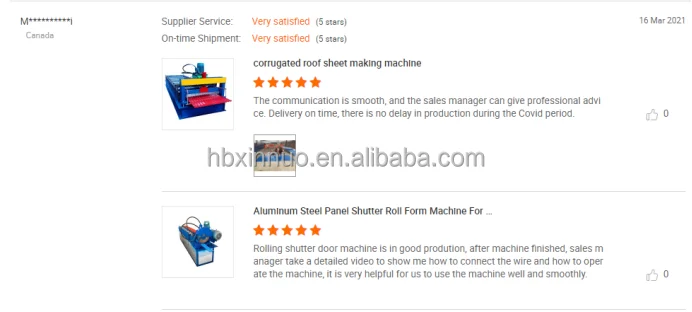

Hebei Xinnuo Roll Forming Machine Co., Ltd., ha e hlahise feela mefuta e fapaneng ea mochini o etsang moqolo oa litsebi, empa hape e nts'etsapele mehala e bohlale ea ho etsa moqolo, mochini oa C&Z oa sebopeho sa mochini, mehala ea mochini oa mochini, mehala ea tlhahiso ea phanele ea sandwich, decking. Mechini ea ho etsa metjhini, metjhini e bobebe ea keel, metjhini e etsang menyako ea shutter slat, metjhini e thellang, metjhini ea likhoerekhoere, joalo-joalo.

Melemo ea Roll Theha Karolo ea Metal

Ho na le melemo e mengata ea ho sebelisa roll form bakeng sa merero ea hau:

- Mokhoa oa ho etsa moqolo o lumella lits'ebetso tse joalo ka ho phunya, ho notlela, le ho tjheseletsa ho etsoa ka mohala. Litsenyehelo tsa mosebetsi le nako ea ts'ebetso ea bobeli li fokotsehile kapa lia felisoa, ho fokotsa litšenyehelo tsa karolo.

- Roll form tooling e lumella boemo bo phahameng ba ho feto-fetoha ha maemo. Sete e le 'ngoe ea lithulusi tsa foromo ea roll e tla etsa hoo e batlang e le bolelele bofe kapa bofe ba karolo e tšoanang ea sefapano. Ha ho hlokahale lisebelisoa tse ngata bakeng sa likarolo tse fapaneng tsa bolelele.

- E ka fana ka taolo e ntlafetseng ea li-dimensional ho feta mekhoa e meng e hlōlisanang ea ho etsa tšepe.

- Ho pheta-pheta ke ntho ea tlhaho ts'ebetsong, ho lumella ho kopanya likarolo tse entsoeng habonolo sehlahisoa sa hau se felileng, le ho fokotsa mathata ka lebaka la "tloaelo" ea ho mamellana.

- Ho etsa roll ke ts'ebetso e potlakileng haholo.

- Ho etsa Roll ho fa bareki sebaka se holimo sa holimo. Sena se etsa hore roll e be khetho e ntle bakeng sa likarolo tsa tšepe tse sa hloekang tse khabisitsoeng kapa likarolo tse hlokang ho qeta joalo ka anodizing kapa ho roala phofo. Hape, sebopeho kapa mohlala o ka phuthoa ka holim'a metsi nakong ea ho theha.

- Ho etsa roll ho sebelisa thepa ka mokhoa o atlehileng ho feta mekhoa e meng ea tlholisano.

- Libopeho tse entsoeng ka roll li ka ntlafatsoa ka marako a masesaane ho feta mekhoa ea tlhōlisano

Ho etsa roll ke ts'ebetso e tsoelang pele e fetolang tšepe ea pampiri hore e be sebopeho se entsoeng ka boenjiniere ho sebelisoa li-roll tse latellanang, 'me e' ngoe le e 'ngoe ea tsona e etsa liphetoho tse ntseng li eketseha ka sebopeho. Kakaretso ea liphetoho tsena tse nyane ka sebopeho ke boemo bo rarahaneng.

-

mochini o etsang moqolo o entsoeng ka masenke

-

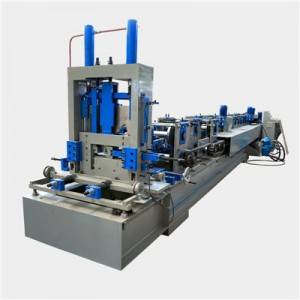

Mochini oa ho etsa moqolo oa CZ purlin

-

Sekhahla se tlase sa mochini o etsang moqolo oa lemati la shutter

-

mochine oa ho etsa mochine o nang le likarolo tse peli

-

C21 mofuta oa lithaele tobetsa Roof panel roll ho etsa mac...

-

mochini o lekanyang

-

hudraulic decoiler

-

mochini o etsang moqolo oa metsi

-

mochini o etsang moqolo o koalang monyako

-

automatic sheet decoiler mochini lithaele seha m...

-

othomathike roll etsa mochini theko barrel cor...

-

Siling e iketsang ea t-grids e nang le sebopeho sa tšepe ea tšepe ...

-

stacker e itekanetseng

-

automatic sheet decoiler mochini lithaele seha m...

-

c profile tšepe moqolo ho etsa mochini auto cz s...

-

c mochini oa purlin