Mofuta o mong oa mochini o etsang purlin

Likarolo tsa lisebelisoa:

Uncoiler e entsoeng ke motho, mochini o etsang Roll, sistimi ea taolo ea komporo, sistimi ea taolo ea haeteroliki, ho itšeha

Lihlahisoa tsa rona li sebelisoa haholo fekthering e fapaneng ea liindasteri, meaho ea baahi, ntlo ea polokelo le mohaho o bonolo oa tšepe

tlhahiso, 'me e na le likarolo tse kang ponahalo e ntle le e tšoarellang.

C Z Purlin Roll Format Machine Mekhatlo e ka sehloohong

1.Echnical parameters

| 1. | Litlhophiso | Manual Uncoiler, Tataiso ea Platform, 9 Shaft Strip Leveler, Main Machine Of Roll Forming, Hydraulic Motor, Pre-Punching Device, Pre-Cutting Device, Hydraulic Station, PLC Control, Supporter Table. |

| 2. | Sistimi ea Taolo | PLC Inverter Encoder Touch Screen |

| 3. | Moralo o ka Sehloohong | 400mm H-Beam |

| 4. | Kakaretso ea Matla | 22 kw |

| 5. | Phepelo ea motlakase | 380V, 3-Mokhahlelo, 50Hz |

| 6. | Ho theha Lebelo | 12-24m/min |

| 7. | Roll Station | 18 li eme |

| 8. | Roller Diameter | 80 limilimithara |

| 9. | Bophara bo Atlehang | 80-300 limilimithara |

| 10. | Ho fepa Botenya | 1.5-3.0 limilimithara |

| 11. | Botenya ba Backboard | 20 limilimithara |

| 12. | Sekhahla Standard | GCr12 |

| 13. | Roller Standard | Gcr15# |

| 14. | Boholo ka Kakaretso | Hoo e ka bang 8500×1000×1400mm |

| 15. | Kakaretso ea Boima | Hoo e ka bang 10T |

HLOKOMELA:Litekanyetso tsohle tsa tekheniki li ka fetoloa ho latela tlhoko ea mosebelisi, 'me feela joalo ka referense.

Melao ea Tefo: 30% ea kakaretso ea boleng ba konteraka e lefuoang ke T / T e le tefo e tlaase, karolo e setseng 70% ea konteraka eohle

boleng bo lokelang ho lefshoa ke T/T ka mor'a ho hlahlojoa ke moreki fekthering ea morekisi pele a fihla.

Delivery: Matsatsi a 30 ka mor'a ho fumana tefo ea pele

Tšebeletso: re romela setsebi naheng ea heno ho ea lokisa mochine.Moreki o lokela ho jara litšenyehelo tsohle tse kenyeletsang: visa,

Litekete tsa ho ea le ho khutla le bolulo bo loketseng, moreki le eena o lokela ho lefa moputso oa 80USD / letsatsi.

Warranty: Tiisetso e lekantsoeng ea likhoeli tse 12

Nakong ea waranti: likarolo ha li lefelloe empa moreki o lefa tefo ea ho tsamaisa thepa.

Hebei Xinnuo Roll Forming Machine Co., Ltd., ha e hlahise feela mefuta e fapaneng ea ho etsa moqolo oa litsebi

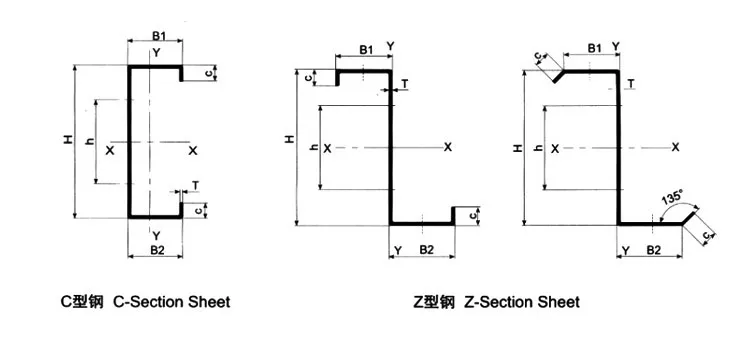

Mechini, empa hape e nts'etsapele mela ea tlhahiso ea othomathike e bohlale,Mochini oa ho etsa Roll oa C Z Purlin,

Highway guardrail roll forming machine line, sandwich panel production line, decking forming machines, light keel.

metjhini, metjhini e etsang menyako ya shutter slat, metjhini e thellang, metjhini ya dithapo, jj.

Lisebelisoa tse matla tsa tekheniki ke tiisetso e tsitsitseng ka ho fetisisa bakeng sa boleng ba lihlahisoa tsa rona. Re sebelisa software ea komporo bakeng sa

moralo oa moralo, setšoantšo sa tlhahiso le setšoantšo sa ho kenya lisebelisoa tsa kaho ea tšepe. Re amohela e tsoetseng pele

tlhahlobo ea k'homphieutha ea digital le ho hlahisa lisebelisoa tsa boleng bo phahameng ba tšepe sebopeho sa tšepe. Tekheniki ea rona e nchafatsoa letsatsi le letsatsi

letsatsi!Marang-rang a rona a thekiso a akaretsa China eohle le lefats'e ka bophara.

Khamphani ea rona e se e holile ka mor'a thekiso ea marang-rang, re ka u fa litšebeletso tse sebetsang hantle le tse khotsofatsang

nakong eohle ea tšebelisano ea rona.Haeba ho hlokahala, re ka u fa tšehetso ea tekheniki ea lehae le ho romella

litheknishiene ho bakeng sa koetliso ea ho kenya le ho sebetsa.

♦ PALE EA BOPHELO BA HAE:

Hebei Xinnuo Roll Forming Machine Co., Ltd., ha e hlahise feela mefuta e fapaneng ea mochini o etsang moqolo oa litsebi, empa hape e nts'etsapele mehala e bohlale ea ho etsa moqolo, mochini oa C&Z oa sebopeho sa mochini, mehala ea mochini oa mochini, mehala ea tlhahiso ea phanele ea sandwich, decking. Mechini ea ho etsa metjhini, metjhini e bobebe ea keel, metjhini e etsang menyako ea shutter slat, metjhini e thellang, metjhini ea likhoerekhoere, joalo-joalo.

Melemo ea Roll Theha Karolo ea Metal

Ho na le melemo e mengata ea ho sebelisa roll form bakeng sa merero ea hau:

- Mokhoa oa ho etsa moqolo o lumella lits'ebetso tse joalo ka ho phunya, ho notlela, le ho tjheseletsa ho etsoa ka mohala. Litsenyehelo tsa mosebetsi le nako ea ts'ebetso ea bobeli li fokotsehile kapa lia felisoa, ho fokotsa litšenyehelo tsa karolo.

- Roll form tooling e lumella boemo bo phahameng ba ho feto-fetoha ha maemo. Sete e le 'ngoe ea lithulusi tsa foromo ea roll e tla etsa hoo e batlang e le bolelele bofe kapa bofe ba karolo e tšoanang ea sefapano. Ha ho hlokahale lisebelisoa tse ngata bakeng sa likarolo tse fapaneng tsa bolelele.

- E ka fana ka taolo e ntlafetseng ea li-dimensional ho feta mekhoa e meng e hlōlisanang ea ho etsa tšepe.

- Ho pheta-pheta ke ntho ea tlhaho ts'ebetsong, ho lumella ho kopanya likarolo tse entsoeng habonolo sehlahisoa sa hau se felileng, le ho fokotsa mathata ka lebaka la "tloaelo" ea ho mamellana.

- Ho etsa roll ke ts'ebetso e potlakileng haholo.

- Ho etsa Roll ho fa bareki sebaka se holimo sa holimo. Sena se etsa hore roll e be khetho e ntle bakeng sa likarolo tsa tšepe tse sa hloekang tse khabisitsoeng kapa likarolo tse hlokang ho qeta joalo ka anodizing kapa ho roala phofo. Hape, sebopeho kapa mohlala o ka phuthoa ka holim'a metsi nakong ea ho theha.

- Ho etsa roll ho sebelisa thepa ka mokhoa o atlehileng ho feta mekhoa e meng ea tlholisano.

- Libopeho tse entsoeng ka roll li ka ntlafatsoa ka marako a masesaane ho feta mekhoa ea tlhōlisano

Ho etsa roll ke ts'ebetso e tsoelang pele e fetolang tšepe ea pampiri hore e be sebopeho se entsoeng ka boenjiniere ho sebelisoa li-roll tse latellanang, 'me e' ngoe le e 'ngoe ea tsona e etsa liphetoho tse ntseng li eketseha ka sebopeho. Kakaretso ea liphetoho tsena tse nyane ka sebopeho ke boemo bo rarahaneng.